I-NiAl cladding powder enamandla okubopha aqinile

Incazelo

Siyaziqhenya ukwethula imikhiqizo emibili esekelwe ku-NiAl powder: i-KF-2 ne-KF-6.Le mikhiqizo emibili isebenzisa izilinganiso ezihlukene ze-NiAl powder futhi inezici eziyingqayizivele kanye nezinhlelo zokusebenza.

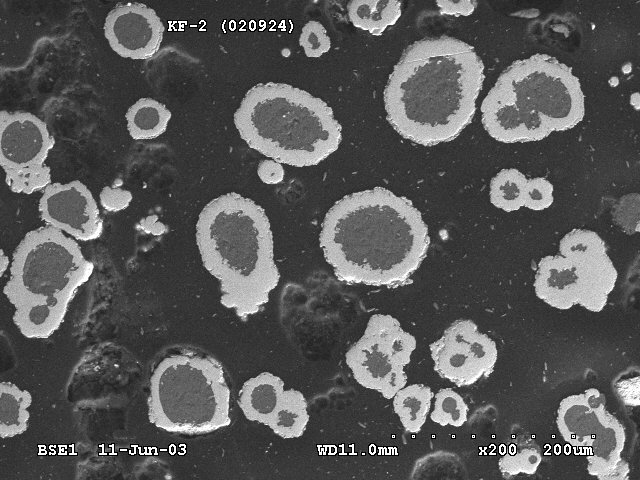

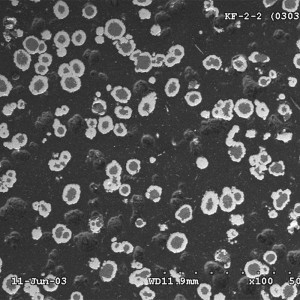

I-KF-2 isebenzisa i-NiAl82/18, equkethe u-82% Ni no-18% Al.Lo mkhiqizo ulungele izinhlelo zokusebenza ezinokushisa okuphezulu okusebenzayo okungu-650°C.Inikeza ukunamathela okuminyene, okusebenzisekayo, ukumelana ne-oxidation, futhi ukumelana nokuguga okunezici zokuzibopha.Kuhlala kukhona ukusabela kwe-exothermic phakathi nenqubo yokufafaza, okuholela emandleni amahle kakhulu okubopha adlula impahla ye-Ni5Al.I-KF-2 ifanele ukukhanda nokwenza kabusha insimbi ye-carbon machable kanye nensimbi engagqwali, futhi ingasetshenziselwa ukubopha izingqimba zobumba nezinto ezigqokekayo.

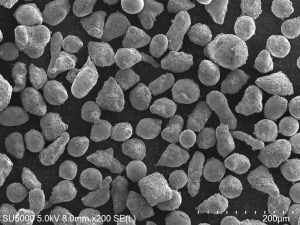

I-KF-6 isebenzisa i-NiAl95/5, equkethe u-95% Ni no-5% Al.Lo mkhiqizo ulungele izinhlelo zokusebenza ezinokushisa okuphezulu kokusebenza okungu-800°C futhi ungasetshenziswa kusetshenziswa izindlela zokufafaza ezahlukahlukene njenge-flame, i-APS, ne-HVOF.Iphinde inikeze ukunamathela okuminyene, okusebenzisekayo, ukumelana ne-oxidation, futhi ukumelana nokugqoka okunezici zokuzibopha.Kuhlala kukhona ukusabela kwe-exothermic phakathi nenqubo yokufafaza, okuholela emandleni amahle kakhulu okubopha.I-KF-6 ingaphinda isetshenziselwe ukulungisa nokwenza kabusha ikhabhoni yensimbi emshinikayo kanye nensimbi engagqwali, kanye nezendlalelo ezibophezelayo zobumba nezinto ezigqokekayo.

Kafushane, zombili i-KF-2 ne-KF-6 ziyimikhiqizo esekwe ku-NiAl powder enikeza amandla amahle kakhulu okubopha kanye nokumelana nokugqoka.I-KF-2, equkethe iphesenti eliphansi le-NiAl powder (NiAl82/18), ifanele izinhlelo zokusebenza ezinokushisa okuphezulu kokusebenza okungu-650 ° C, kuyilapho i-KF-6, enephesenti eliphezulu le-NiAl powder (NiAl95/5), ingaphatha amazinga okushisa aphakeme aze afike ku-800°C futhi ingasetshenziswa kusetshenziswa izindlela ezihlukene zokufafaza.Yomibili le mikhiqizo ilungele ukukhanda nokukhiqiza kabusha i-carbon steel machinable nensimbi engagqwali, kanye nezendlalelo ezibophayo zezitsha zobumba nezinto ezigqokekayo.Ukukhetha phakathi kwe-KF-2 ne-KF-6 kuncike ezidingweni ezithile zohlelo lokusebenza kanye nezinga lokushisa eliphezulu elidingekayo.

Imikhiqizo efanayo

| Ibhrendi | Igama Lomkhiqizo | AMPERIT | I-METCO/AMDRY | WOKA | I-PRAXAIR | I-PAC |

| KF-2 | NiAl82/18 | 404NS | ||||

| KF-6 | NiAl95/5 | 282 | 956450NS | NI-109 | 906 |

Ukucaciswa

| Ibhrendi | Igama Lomkhiqizo | Ikhemistri (wt%) | Ukuqina | Izinga lokushisa | Izakhiwo Nokusebenza | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | I-Al2O3 | I-MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | U-Bal. | I-HRC 20 | ≤ 800ºC | •Flame, APS, Max.izinga lokushisa lokusebenza 650°C. •Imelana ne-oxidation eminyene futhi egqokekayo. | ||||||||

| KF-6 | NiAl95/5 | 5 | U-Bal. | I-HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max.izinga lokushisa lokusebenza 800°C •Imelana ne-oxidation eminyene futhi egqokekayo | ||||||||

| KF-20 | I-Ni-MoS₂ | 22 | U-Bal. | I-HRC 20 | ≤ 500ºC | •Isetshenziselwa izingxenye zokuvala ezihambayo nezindandatho zokuvala ezigayayo • Ingasetshenziswa njengento ephansi yokungqubuzana | ||||||||

| I-KF-21T | I-Ni-Graphite 75/25 | 25 | U-Bal. | I-HRC 20 | ≤ 480ºC | •Flame, Max.izinga lokushisa lokusebenza 480°C 1. Ukugqoka izinto ze-turbo compressor •Isebenza ku-nickel alloy nezingxenye zensimbi •Imikhiqizo enokuqukethwe okuphezulu kwe-graphite ifanele izingxenye ze-titanium ngaphandle komphetho •Okuqukethwe okuphezulu kwe-graphite kuzothuthukisa ukusebenza kokugcoba •Okuqukethwe kwe-nickel ephezulu kuzothuthukisa ukumelana nokuguguleka •Imikhiqizo efanayo ihlukile ngenxa yokucaciswa okuhlukile kwe-OEM | ||||||||

| I-KF-22T/R | I-Ni-Graphite 60/40 | 50 | U-Bal. | I-HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | I-Ni-Graphite 75/25 | 25 | U-Bal. | I-HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | I-Ni-Al2O3 77/23 | 23 | U-Bal. | I-HRC 40 | ≤ 800ºC | •I-Flame, i-APS, ayijwayelekile •Ingasetshenziselwa ukuncibilikisa i-crucible, indawo yokugcina uphawu nendawo yokubumba njengongqimba oluvikelayo | ||||||||

| KF-56 | I-Ni-WC 16/84 | U-Bal. | 12 | I-HRC 62 | ≤ 400ºC | •I-Flame, i-APS, ayijwayelekile •Ukumelana nokushaywa ngesando, ukuguguleka, ukuhuzuka nokuslayida | ||||||||

| KF-50 | I-Ni-WC10/90 | U-Bal. | 10 | I-HRC 62 | ≤ 400ºC | •Ilangabi, alijwayelekile •Ukumelana nokushaywa ngesando, ukuguguleka, ukuhuzuka nokuslayida | ||||||||

| KF-91Fe | I-Fe-WC | 4 | 27 | 9.5 | U-Bal. | 5.5 | I-HRC 40 | ≤ 550ºC | •Flame, APS, irregular, Max.izinga lokushisa lokusebenza 815°C. •Gqoka okokunamathelayo okungazweli, okungasetshenziselwa ukulungisa amabhuleki ethangi | |||||

| KF-110 | I-NiCr-Al 95/5 | 5 | 7.5 | U-Bal. | I-HRC 20 | ≤ 800ºC | •Flame, APS, Max.izinga lokushisa lokusebenza 980°C. •Ukufafaza nge-Plasma ngokuzibophezela | |||||||

| KF-113A | I-NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | I-HRC 20 | ≤ 900ºC | •APS,HVOF, irregular, Max.izinga lokushisa lokusebenza 980°C. •Kusebenza ekulungiseni izinga lokushisa eliphezulu lokubopha ungqimba noma izingxenye ezigugile / ezingacutshungulwe ngokungafanele | |||||||||

| KF-133 | NiMoAl | 5 | 5 | U-Bal. | I-HRC 20 | ≤ 650ºC | • Ukuzibophezela, ukunamathela okuvamile okuqinile ukuze kufakwe isicelo •Iqinile, inokumelana nokugqwala okuhle nokusebenza okunomthelela •Isetshenziselwa izingxenye zomshini, isihlalo sokuthwala kanye nevalvu | |||||||

| KF-31 | I-Ni-Diatomite 75/25 | •I-Flame, APS, irregular, Max.izinga lokushisa lokusebenza 650°C. •Ngokwemboza ngophawu olugayayo, okuhlanganisa izingxenye ezigudlukayo zophawu, izindandatho zophawu olugayayo, izinto ezingqubuzanayo eziphansi | ||||||||||||