I-Ni-Graphite Cladding powder ene-conductivity kagesi

Incazelo

I-Ni-Graphite Cladding powder iyisisetshenziswa esikhethekile esiklanyelwe ukuhlinzeka ngokusebenza okuphezulu kwezicelo zezimboni ezifunayo.Le mpushana esunguliwe ifakwe amakhemikhali ngokugcwala okuphezulu kwe-nickel ne-graphite, okuyenza ibe yinketho ekahle yokusebenzisa ukugqoka izinto ze-turbo compressor, i-nickel alloy, nezingxenye zensimbi.

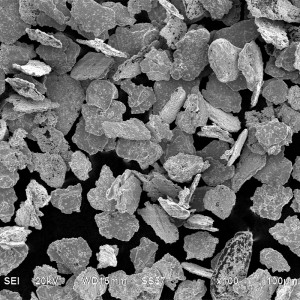

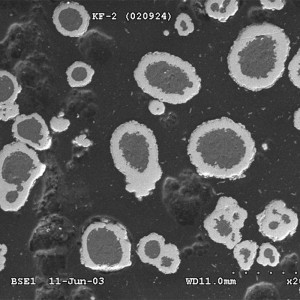

Esinye sezici ezibalulekile ze-Ni-Graphite Cladding powder okuqukethwe kwayo kwe-graphite ephezulu.Lesi sici sithuthukisa ukusebenza kokugcotshwa kwempushana, ikwenze kube ukukhetha okudumile ukusetshenziswa ezingxenyeni ze-titanium ezingenawo umkhawulo.Ukwengeza, okuqukethwe okuphezulu kwe-nickel ye-powder kuthuthukisa ukumelana kwayo nokuguguleka, iqinisekisa ukuthi inikeza ukusebenza kahle ezindaweni ezinonya zezimboni.

I-Ni-Graphite Cladding powder itholakala ngezindlela ezimbili ezihlukene: i-KF-21 Ni-Graphite 75/25 kanye ne-KF-22 Ni-Graphite 60/40.Lezi zinhlanganisela ezimbili zinezilinganiso ezihlukile zokuqukethwe kwe-nickel ne-graphite, okuzenza zifanele izinhlobo ezahlukene zezinhlelo zokusebenza zezimboni.Isibonelo, i-KF-21 Ni-Graphite 75/25 inokuqukethwe kwe-nickel okuphezulu, okuyenza ifaneleke ukusetshenziswa ezinhlelweni ezidinga ukumelana nokuguguleka okuphakeme.

Ngaphezu kwezici zayo zokusebenza okuphezulu, i-Ni-Graphite Cladding powder nayo iguquguquka kakhulu.Ingasetshenziswa ezinhlobonhlobo zezinhlelo zokusebenza zezimboni, okuhlanganisa i-turbo compressors, i-nickel alloy, nezingxenye zensimbi.Ngaphezu kwalokho, ukumelana kwayo nelangabi kanye nezinga lokushisa eliphezulu lokusebenza elingu-480°C kuyenza ibe ukukhetha okuthembekile ukuze isetshenziswe ezinhlelweni zokushisa okuphezulu.

Uma kuziwa ekukhetheni i-Ni-Graphite Cladding powder efanele yohlelo lwakho lokusebenza lwezimboni, kubalulekile ukucabangela ukucaciswa okuqondile kwe-OEM kwempahla yakho.I-KF-21 ifana ne-AMPERIT 205, METCO/AMDRY 307NS, PRAXAIR NI-114, ne-PAC 138, kuyilapho i-KF-22 ifana ne-AMPERIT 200 ne-Durabrade 2211.

Sengiphetha, i-Ni-Graphite Cladding powder iyisisetshenziswa esikhethekile esihlinzeka ngokusebenza okuphezulu ekufuneni izicelo zezimboni.Okuqukethwe kwayo okuphezulu kwe-graphite nokuqukethwe kwe-nickel ephezulu kuyenza ibe inketho ekahle ukusetshenziswa ekugqokeni izinto ze-turbo compressor, i-nickel alloy, nezingxenye zensimbi.Ngokuguquguquka kwayo, ukumelana nelangabi, kanye nezinga lokushisa eliphezulu lokusebenza, i-Ni-Graphite Cladding powder iyisinqumo esinokwethenjelwa ezinhlobonhlobo zezicelo zezimboni.

Imikhiqizo efanayo

| Ibhrendi | Igama Lomkhiqizo | AMPERIT | I-METCO/AMDRY | WOKA | I-PRAXAIR | I-PAC |

| I-KF-21T/R | I-Ni-Graphite 75/25 | 205 | 307NS | NI-114 | 138 | |

| I-KF-22T/R | I-Ni-Graphite 60/40 | 200 | Durabrade 2211 |

Ukucaciswa

| Ibhrendi | Igama Lomkhiqizo | Ikhemistri (wt%) | Ukuqina | Izinga lokushisa | Izakhiwo Nokusebenza | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Al | W | Mo | Cr | I-Al2O3 | I-MoS2 | WC | C | Fe | Ni | |||||

| KF-2 | NiAl82/18 | 20 | U-Bal. | I-HRC 20 | ≤ 800ºC | •Flame, APS, Max.izinga lokushisa lokusebenza 650°C. •Imelana ne-oxidation eminyene futhi egqokekayo. | ||||||||

| KF-6 | NiAl95/5 | 5 | U-Bal. | I-HRC 20 | ≤ 800ºC | •Flame, APS, HVOF, Max.izinga lokushisa lokusebenza 800°C •Imelana ne-oxidation eminyene futhi egqokekayo | ||||||||

| KF-20 | I-Ni-MoS₂ | 22 | U-Bal. | I-HRC 20 | ≤ 500ºC | •Isetshenziselwa izingxenye zokuvala ezihambayo nezindandatho zokuvala ezigayayo • Ingasetshenziswa njengento ephansi yokungqubuzana | ||||||||

| I-KF-21T | I-Ni-Graphite 75/25 | 25 | U-Bal. | I-HRC 20 | ≤ 480ºC | •Flame, Max.izinga lokushisa lokusebenza 480°C 1. Ukugqoka izinto ze-turbo compressor •Isebenza ku-nickel alloy nezingxenye zensimbi •Imikhiqizo enokuqukethwe okuphezulu kwe-graphite ifanele izingxenye ze-titanium ngaphandle komphetho •Okuqukethwe okuphezulu kwe-graphite kuzothuthukisa ukusebenza kokugcoba •Okuqukethwe kwe-nickel ephezulu kuzothuthukisa ukumelana nokuguguleka •Imikhiqizo efanayo ihlukile ngenxa yokucaciswa okuhlukile kwe-OEM | ||||||||

| I-KF-22T/R | I-Ni-Graphite 60/40 | 50 | U-Bal. | I-HRC 20 | ≤ 480ºC | |||||||||

| KF-21R | I-Ni-Graphite 75/25 | 25 | U-Bal. | I-HRC 20 | ≤ 480ºC | |||||||||

| KF-45 | I-Ni-Al2O3 77/23 | 23 | U-Bal. | I-HRC 40 | ≤ 800ºC | •I-Flame, i-APS, ayijwayelekile •Ingasetshenziselwa ukuncibilikisa i-crucible, indawo yokugcina uphawu nendawo yokubumba njengongqimba oluvikelayo | ||||||||

| KF-56 | I-Ni-WC 16/84 | U-Bal. | 12 | I-HRC 62 | ≤ 400ºC | •I-Flame, i-APS, ayijwayelekile •Ukumelana nokushaywa ngesando, ukuguguleka, ukuhuzuka nokuslayida | ||||||||

| KF-50 | I-Ni-WC10/90 | U-Bal. | 10 | I-HRC 62 | ≤ 400ºC | •Ilangabi, alijwayelekile •Ukumelana nokushaywa ngesando, ukuguguleka, ukuhuzuka nokuslayida | ||||||||

| KF-91Fe | I-Fe-WC | 4 | 27 | 9.5 | U-Bal. | 5.5 | I-HRC 40 | ≤ 550ºC | •Flame, APS, irregular, Max.izinga lokushisa lokusebenza 815°C. •Gqoka okokunamathelayo okungazweli, okungasetshenziselwa ukulungisa amabhuleki ethangi | |||||

| KF-110 | I-NiCr-Al 95/5 | 5 | 7.5 | U-Bal. | I-HRC 20 | ≤ 800ºC | •Flame, APS, Max.izinga lokushisa lokusebenza 980°C. •Ukufafaza nge-Plasma ngokuzibophezela | |||||||

| KF-113A | I-NiCrAl-CoY2O3 | Cr+Al:20, Ni+Co:75 | I-HRC 20 | ≤ 900ºC | •APS,HVOF, irregular, Max.izinga lokushisa lokusebenza 980°C. •Kusebenza ekulungiseni izinga lokushisa eliphezulu lokubopha ungqimba noma izingxenye ezigugile / ezingacutshungulwe ngokungafanele | |||||||||

| KF-133 | NiMoAl | 5 | 5 | U-Bal. | I-HRC 20 | ≤ 650ºC | • Ukuzibophezela, ukunamathela okuvamile okuqinile ukuze kufakwe isicelo •Iqinile, inokumelana nokugqwala okuhle nokusebenza okunomthelela •Isetshenziselwa izingxenye zomshini, isihlalo sokuthwala kanye nevalvu | |||||||

| KF-31 | I-Ni-Diatomite 75/25 | •I-Flame, APS, irregular, Max.izinga lokushisa lokusebenza 650°C. •Ngokwemboza ngophawu olugayayo, okuhlanganisa izingxenye ezigudlukayo zophawu, izindandatho zophawu olugayayo, izinto ezingqubuzanayo eziphansi | ||||||||||||