I-Cobalt Base Alloy ekwazi ukumelana nokuguga nokugqwala

Incazelo

I-KF-3321 iyi-cobalt-based alloy powder enokumelana okuhle kakhulu kokugqoka kanye nokumelana ne-oxidation ephezulu.Yakhiwe nge-cobalt, i-chromium, i-tungsten, i-nickel, i-silicon, ne-carbon, futhi ingase iqukathe amanani amancane e-aluminium, i-niobium, i-tantalum, nezinye izakhi ze-alloy.

Izakhiwo Zempushana

Usayizi Wezinhlayiyana:I-KF-3321 inobubanzi bezinhlayiyana zezinhlayiyana -140 kuya ku-+325 mesh, okuyenza ifanelekele izinhlelo zokusebenza ezihlukahlukene lapho kudingeka khona usayizi wezinhlayiyana.

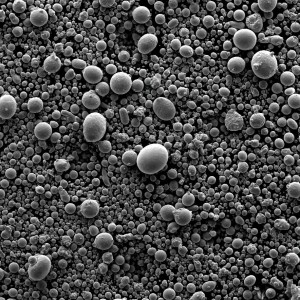

Uhlobo:I-KF-3321 iyimpushana ye-athomu yegesi, okusho ukuthi ikhiqizwa ngokuncibilikisa i-alloy bese i-atomizing nge-high-pressure gas.Lokhu kubangela isimo sempushana esiyindilinga, esihlinzeka ngokugeleza okuhle nokuminyana kokupakisha.

Ukwakhiwa:I-KF-3321 iyi-cobalt-based alloy powder equkethe iphesenti eliphezulu le-cobalt, elinikeza ukumelana nokugqokwa okuhle kakhulu.Ukwengezwa kwe-chromium ne-tungsten kuthuthukisa ngokwengeziwe ukumelana kwayo nokugqoka kanye nokumelana ne-oxidation ephezulu yezinga lokushisa.I-Nickel, i-silicon, ne-carbon inikeza amandla engeziwe nokumelana nokugqwala ku-alloy.

Isicelo

I-KF-3321 iyimpuphu ye-alloy enemisebenzi eminingi engasetshenziswa ezimbonini ezihlukahlukene zokufaka izicelo ezidinga ukumelana nokugqokwa okuhle kakhulu kanye nokumelana ne-oxidation ephezulu.Ezinye izinhlelo zokusebenza ezijwayelekile zifaka:

Ama-valve we-high-temperature pressure:Ukumelana ne-high-temperature oxidation kwe-KF-3321 kuyenza ibe into efanelekile yamavalvu omfutho wezinga eliphezulu lokushisa.

Amazinyo abone:Ukumelana nokuqina kwe-KF-3321 kuyenza ifanelekele ukusetshenziswa emazinyweni asaha, adinga into eqinile engamelana nengcindezi kanye nobunzima bokusika.

Izikulufu ze-Extrusion:Ukumelana nokugqokwa kwe-KF-3321 kanye nokumelana ne-oxidation ephezulu yezinga lokushisa kuyenza ibe yisinqumo esihle sokusebenzisa izikulufo ze-extrusion, ezidinga into engakwazi ukumelana namazinga okushisa aphezulu kanye nezingcindezi zenqubo ye-extrusion.

Okufanayo ne-St12:I-KF-3321 inezinto ezifanayo ne-St12, insimbi enekhabhoni ephansi evame ukusetshenziswa embonini yezimoto.Kodwa-ke, i-KF-3321 inokumelana nokugqokwa okungcono kakhulu kanye nokumelana ne-oxidation ephezulu yezinga lokushisa kune-St12, okuyenza ibe ukukhetha okuphezulu kwezinhlelo zokusebenza ezidinga ukumelana nokugqoka okuphezulu nokuzinza kwezinga lokushisa eliphezulu.

Sekukonke, i-KF-3321 iyi-powder alloy esebenza kahle kakhulu enikeza ukumelana nokugqoka okuhle kakhulu kanye nokumelana ne-oxidation ephezulu.Izakhiwo zayo eziguquguqukayo ziyenza ifanelekele uhla olubanzi lwezicelo ezimbonini ezahlukahlukene.

Imikhiqizo efanayo

| Ibhrendi | Igama Lomkhiqizo | AMPERIT | I-METCO/AMDRY | WOKA | I-PRAXAIR | I-PAC |

| KF-331 | I-CoCrMoSi | 340 | 66/3002 | I-CO109 / 1247 | T400 | |

| KF-333 | I-CoCrMoSi | 342 | 68/3001/4800 | I-CO111 / 1248 | T800 | |

| KF-332 | CoCrWCNiSi | |||||

| KF-3321 | CoCrWCNiSi | |||||

| KF-3322 | CoCrWCNiSi | Okufanayo 344 | 4060 | I-CO106 1256 | 6 46 | |

| KF-3323 | CoCrWCNiSi | |||||

| KF-3324 | CoCrWCNiSi | 344 | 45 x40 | I-CO105 / CO285 | 90 | |

| KF-3325 | CoCrWCNiSi |

Ukucaciswa

| Ibhrendi | Igama Lomkhiqizo | Ikhemistri (wt%) | Ukuqina | Izinga lokushisa | Izakhiwo Nokusebenza | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | W | C | Ni | Si | B | Mo | Co | |||||

| KF-331 | I-CoCrMoSi | 8 | 2.6 | 28 | U-Bal. | I-HRC 54 | ≤ 840ºC | •Ukumelana nokugqoka, ukumelana nokunwaya •Ukumelana nokugqwala | ||||

| KF-333 | I-CoCrMoSi | 17.5 | 3.4 | 35 | U-Bal. | HRC53 | ≤ 840ºC | •Ukumelana nokugqoka, ukumelana nokunwaya •Ukumelana nokugqwala | ||||

| KF-332 | CoCrWCNiSi | 25 | 7.5 | 0.8 | 10 | 1 | U-Bal. | I-HRC 30 | ≤ 840ºC | •Isihlalo sevalvu •Ukuzala •I-Blade •Efana ne-St1 | ||

| KF-3321 | CoCrWCNiSi | 30 | 4 | 1.5 | 3 | 1.4 | 4 | U-Bal. | HRC45 | ≤ 840ºC | •I-PTA, i-APS, i-HVOF, i-laser cladding, i-spherical •Amavalvu omfutho ophakeme wokushisa, amazinyo asaha, izikulufu zokuphuma •Efana ne-St12 | |

| KF-3322 | CoCrWCNiSi | 30 | 4.5 | 1 | 3 | 1.4 | U-Bal. | I-HRC 40 | ≤ 840ºC | •I-PTA, i-APS, i-HVOF, i-laser cladding, i-spherical •Amavalvu enjini, amazinga okushisa aphezulu, ama-turbo engine blades •Efana ne-St6 •Ukumelana nokugqokwa okuhle kumazinga okushisa aphezulu | ||

| KF-3323 | CoCrWCNiSi | 28 | 0.25 | 3 | 1 | 5.5 | U-Bal. | HRC55 | ≤ 840ºC | •Ama-turbine blades •Ama-valve oketshezi •Isihlalo sevalvu | ||

| KF-3324 | CoCrWCNiSi | 25.5 | 7.5 | 0.5 | 10.5 | 1 | U-Bal. | I-HRC 30 | ≤ 840ºC | •Izibunjwa zokukhipha •Ama-turbine blades | ||

| KF-3325 | CoCrWCNiSi | 21.0 | 5 | 0.1 | 1 | 1.6 | 2.4 | U-Bal. | HRC50 | ≤ 840ºC | •I-PTA, i-APS, i-HVOF, i-laser cladding, i-spherical •Ukumelana nezinga lokushisa eliphezulu •Amavalvu esithuthuthu •Ukuzikhipha | |