I-Precious Metal Cr enokumelana nokugqwala

Incazelo

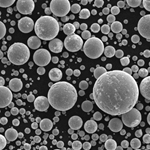

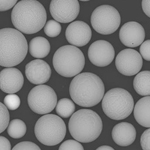

I-Chromium powder iyimpushana eyinsimbi esetshenziswa kakhulu ethola ukusetshenziswa ezimbonini ezahlukahlukene.Ikhiqizwa ngokunciphisa i-chromium oxide nge-aluminium powder esithandweni sokushisa okuphezulu, okuholela kumpushana ompunga omuhle, omnyama nokuhlanzeka okuphezulu.

Enye yezinto eziphawuleka kakhulu ze-chromium powder ukumelana kwayo nokugqwala okuhle kakhulu.Isetshenziswa kabanzi ekukhiqizeni insimbi engagqwali kanye nama-alloys asezingeni lokushisa eliphezulu ezimbonini ze-aerospace nezimboni zezimoto.Izakhiwo ze-Chromium ezimelana nokugqwala zisiza ekwandiseni ukuqina neminyaka yokuphila yalezi zingxubevange, zizenze zilungele ukusetshenziswa ezindaweni ezinokhahlo.

Ngaphandle kokusetshenziswa kwayo ekukhiqizeni ingxubevange yensimbi, impushana ye-chromium ibuye isetshenziswe njengombala lapho kukhiqizwa opende, oyinki nodayi.Usayizi wezinhlayiyana ocolekile we-chromium powder ukwenza kube ukukhetha okufanelekile kokukhiqizwa kwekhwalithi ephezulu yensimbi.Lawa maqede ahlinzeka ngokuhlala isikhathi eside, ukumelana nokugqwala okucwebezelayo, okuwenza afanelekele ukusetshenziswa ezintweni ezihlukahlukene, okuhlanganisa izimboni zezimoto kanye ne-aerospace.

I-Chromium powder iphinde isetshenziswe ekukhiqizeni ezinye izinto, njengama-alloys e-nickel-chromium, asetshenziswa kakhulu ekwenzeni izinto zokushisa.Lawa ma-alloys alungele ukusetshenziswa ekusetshenzisweni kwezinga lokushisa eliphezulu, ngenxa yamaphuzu awo aphezulu okuncibilika kanye nokumelana nokugqwala.

Kafushane, i-chromium powder iyinto eguquguqukayo enezakhiwo ezinhle kakhulu zokumelana nokugqwala.Isetshenziswa kabanzi ekukhiqizeni insimbi engagqwali, ama-alloys ashisa kakhulu, kanye nama-metallic finishes.Izakhiwo zayo zikwenza kube ukukhetha okufanele ukusetshenziswa ezindaweni ezinokhahlo kanye nezicelo ezishisa kakhulu, okuyenza ibe yinto edumile ezimbonini ezahlukahlukene.

I-Chemistry

| Isici | Cr | O | |

|---|---|---|---|

| Inqwaba (%) | Ubumsulwa ≥99.9 | ≤0.1 | |

Impahla ebonakalayo

| I-PSD | Izinga lokugeleza (isekhondi/50g) | Ukuminyana Okubonakalayo (g/cm3) | I-Sphericity | |

|---|---|---|---|---|

| 30-50 μm | ≤40s/50g | ≥2.2g/cm3 | ≥90% | |