I-MCrAlY Alloy enokumelana nezinga lokushisa eliphezulu

Incazelo

Ibhrendi:KF-301 KF-308 KF-309 KF-336 KF-337 KF-339… Uhlobo: Igesi eyenziwe nge-athomu

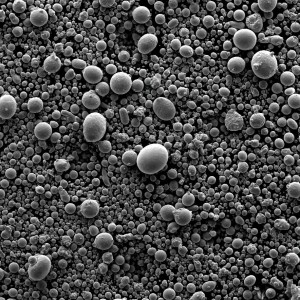

Izakhiwo Zempushana:Ukwakhiwa Kwekhemikhali: MCrAlY (M = Fe, Ni, noma Co) Usayizi Wengxenye: -45 +15 µm Ubumsulwa: ≥ 99.5%

Isicelo:Izimpushana ze-MCrAlY Alloy zisetshenziswa kakhulu ekusetshenzisweni kwezinga lokushisa eliphezulu ngenxa yezakhiwo zazo ezihlukile.Avame ukusetshenziswa njengamajazi ebhondi kuma-metallurgical rolls, ama-hot dip sink rolls, namaroli okushisa okushisa.Ukwengeza, asetshenziswa embonini ye-aerospace ekwenzeni izingxenye ze-turbine yegesi, izihlangu zokushisa, nama-aero engine blades.

Izici ze-MCrAlY Alloy

I-1.I-High Temperature Resistance: I-MCrAlY Alloy powders ibonisa ukumelana okuhle kakhulu nokushisa okuphezulu.Lesi sakhiwo sizenza zilungele ukusetshenziswa ezinhlelweni zokushisa eziphezulu ezifana nezinjini zegesi, iziko lokushisa ukushisa, namaroli e-metallurgical.

2.Izakhiwo Ze-Antioxidant: Izimpushana ze-MCrAlY Alloy zimelana kakhulu ne-oxidation emazingeni okushisa aphezulu, okuzenza zilungele ukusetshenziswa ezindaweni ezinokhahlo lapho i-oxidation ingenzeka khona, njengakuma-turbine egesi nezihlangu zokushisa.

I-3.I-Hot Corrosion Resistance: Izimpushana ze-MCrAlY Alloy zibonisa ukumelana okuhle kakhulu nokugqwala okushisayo, okuzenza zilungele ukusetshenziswa ezindaweni lapho impahla ivezwa endaweni egqwalayo emazingeni okushisa aphezulu.

I-4.Thermal Barrier Substrate: I-MCrAlY Alloy powders ivame ukusetshenziswa njenge-thermal barrier substrates ngenxa ye-conductivity yabo ye-thermal enhle kakhulu kanye nezakhiwo zokwandisa ukushisa.Zisetshenziswa ngokuhambisana nezingubo ze-ceramic ukuvikela izinto ezingaphansi ezindaweni ezishisa kakhulu.

Sekukonke, izimpushana ze-MCrAlY Alloy ziyizinto eziguquguqukayo ezibonisa izakhiwo ezinhle kakhulu zezinga lokushisa eliphezulu, okuzenza zilungele ukusetshenziswa ezinhlotsheni zezinhlelo zokusebenza kuzo zonke izimboni ezahlukene.Izici zabo eziyingqayizivele, ezihlanganisa ukumelana nezinga lokushisa eliphezulu, izakhiwo ze-antioxidant, ukumelana nokugqwala okushisayo, kanye nezakhiwo ze-thermal barrier substrate, kubenza babe ukukhetha okuthandwayo kwezicelo zokushisa okuphezulu.

Imikhiqizo efanayo

| Ibhrendi | Igama Lomkhiqizo | AMPERIT | I-METCO/AMDRY | WOKA | I-PRAXAIR | I-PAC |

| KF-301 | ||||||

| KF-308 | I-NiCrAlY | 9621 | ||||

| KF-309 | NiCoCrAlY | |||||

| KF-336 | I-CoCrAlSiY | |||||

| KF-337 | I-CoNiCrAlY | 9954 | ||||

| KF-339 | I-CoCrAlYTaSiC |

Ukucaciswa

| Ibhrendi | Igama Lomkhiqizo | Ikhemistri (wt%) | Ukuqina | Izinga lokushisa | Izakhiwo Nokusebenza | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cr | Al | Y | Ta | Si | C | Co | Ni | |||||

| KF-301 | •APS, HVOF, detonation-gun, spherical •Amajazi amabhondi okushisa aphezulu | |||||||||||

| KF-308 | I-Nickel Chromium Aluminium Yttrium Alloy | 25 | 11 | 1 | U-Bal. | HRC 20-30 | ≤ 950ºC | •I-Metallurgical roll, i-hot dip sink roll, isithando somlilo sokushisa. •Ama-aero engine blades, i-gas turbine, isivikelo sokushisa | ||||

| KF-309 | I-Nickel Cobalt I-Chromium Aluminium Yttrium Alloy | 25 | 6 | 0.5 | 22 | U-Bal. | HRC 20-30 | ≤ 950ºC | •Ukumelana nokushisa okuphezulu, i-antioxidant. •Hot ukugqwala ukumelana. •I-thermal barrier substrate | |||

| KF-336 | I-Cobalt Chromium Aluminium Silicon Yttrium Alloy | 29 | 7 | 0.5 | 3 | U-Bal. | HRC 20-30 | ≤ 1000ºC | •Ukumelana nokushisa okuphezulu, i-antioxidant. •Hot ukugqwala ukumelana, substrate | |||

| KF-337 | I-Cobalt Chromium Aluminium Yttrium Alloy | 23 | 6 | 0.4 | U-Bal. | 30 | HRC 20-30 | ≤ 1050ºC | •Ukumelana nokushisa okuphezulu, i-antioxidant. •Hot ukugqwala ukumelana, thermal barrier substrate | |||

| KF-339 | I-Cobalt Chromium Aluminium Yttrium Alloy | 24 | 7.5 | 0.8 | 10 | 0.8 | 2 | U-Bal. | ≤ 1100ºC | •APS, HVOF, detonation-gun, spherical •Metallurgical roll, izinga lokushisa eliphezulu annealing isithando roll. •Ama-aero engine rotor blades, ama-guide blades nama-gas turbine blades | ||